How to Choose the Right Gas Flow Meter for Your Needs?

Choosing the right gas flow meter can be a challenging task. With various types available, it’s crucial to identify your specific needs. Gas flow meters measure the volume of gas that passes through a certain point. They are essential in various applications, from industrial processes to residential usage.

Understanding the key aspects of gas flow meters is vital for making an informed decision. Consider factors such as accuracy, size, and compatibility. Different industries may demand different specifications. For example, a high-temperature environment might require a specialized meter. This diversity can lead to confusion. It’s not just about picking one off the shelf.

It's also important to reflect on the long-term reliability of the device. Will it hold up under daily use? Maintenance is another consideration. Some models require more upkeep than others. Making the wrong choice could result in costly repairs or replacements. Therefore, taking the time to evaluate your options pays off in the end.

Understanding Different Types of Gas Flow Meters Available in the Market

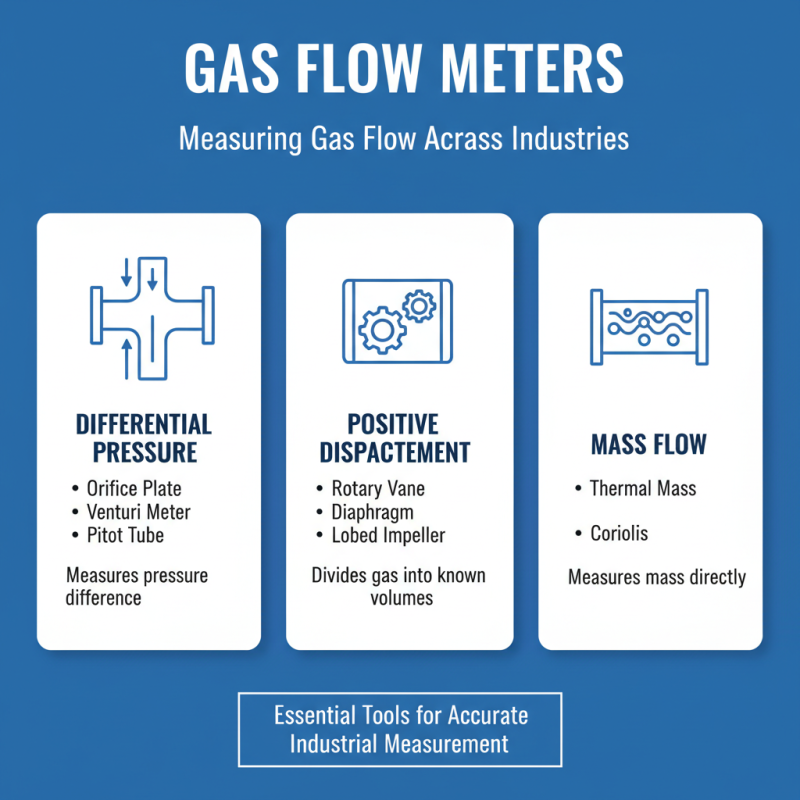

Gas flow meters are essential tools used across various industries, measuring the flow rate of gases in pipelines. Understanding the types available is vital for effective application. There are several main categories: differential pressure meters, positive displacement meters, and mass flow meters.

Differential pressure meters are widely used. They can measure flow without requiring intricate equipment. According to industry reports, they represent about 40% of the market share. These meters estimate flow based on pressure drop, making them versatile. However, they can be susceptible to flow profile disturbances, which can affect accuracy. This makes them less suitable for applications with fluctuating flow conditions.

On the other hand, mass flow meters account for around 30% of the market. These devices measure the mass of the gas directly. They provide high accuracy, especially important in critical applications. Yet, they can be costly and require regular calibration. Many users report struggling with installation complexities. This raises the question of whether the investment is justified for all applications. Evaluating these trade-offs is crucial for selecting the appropriate meter, ensuring that users meet both operational needs and budgets.

Factors to Consider When Selecting a Gas Flow Meter for Specific Applications

Choosing the right gas flow meter requires careful consideration. Various factors impact the decision. The most important is the application. Different industries have distinct needs. For example, oil and gas require accuracy under high pressure. In HVAC systems, compact and precise meters are essential.

Accuracy can vary significantly. According to recent studies, flow meters can have an error margin of up to 5%. This may be acceptable in some cases, but it’s critical in others. A food processing facility, for instance, cannot tolerate any inaccuracies. The same goes for medical applications. These sectors often necessitate compliance with strict regulatory standards.

Another factor to consider is the types of gases being measured. Some meters work well with natural gas but not with synthetic gases. The temperature range also matters. Meters must operate effectively in both high and low temperatures. Examining these aspects will help avoid costly mistakes. It’s beneficial to consult with experts or review industry reports before making a final decision.

Evaluating Accuracy and Measurement Range in Gas Flow Meters

When selecting a gas flow meter, evaluating accuracy and measurement range is crucial. Accuracy impacts the reliability of data. In gas applications, even a small error can lead to significant issues. According to industry reports, achieving an accuracy level of ±1% is typical for high-quality devices. However, not all gas meters meet this standard. Some may have larger error margins, affecting precision in critical applications.

The measurement range also plays a vital role. Most gas flow meters measure in different ranges. Devices can range from 0 to 5000 SCFM (Standard Cubic Feet per Minute) or more. A wide measurement range is essential for applications with varying flow rates. Reports suggest that meters with a higher turndown ratio provide better accuracy across a broader range. Yet, choosing a meter with an excessive range may lead to suboptimal performance at specific flow rates.

In this context, a thorough understanding of application-specific needs is necessary. Flow conditions, gas types, and environmental factors should guide your choice. Do not overlook calibration frequency as well. Monthly calibration may be needed for some sensitive systems. This creates additional maintenance work and potential costs. It’s essential to balance these factors before making a decision.

How to Choose the Right Gas Flow Meter for Your Needs? - Evaluating Accuracy and Measurement Range in Gas Flow Meters

| Type of Flow Meter | Accuracy (%) | Measurement Range (Nm3/h) | Operating Pressure (bar) | Temperature Range (°C) |

|---|---|---|---|---|

| Positive Displacement Meter | ±1.0 | 1 - 100 | 0 - 30 | -20 to 60 |

| Thermal Mass Flow Meter | ±2.0 | 0.1 - 500 | -1 - 10 | -40 to 150 |

| Ultrasonic Flow Meter | ±1.5 | 2 - 2000 | 0 - 80 | -20 to 100 |

| Vortex Flow Meter | ±1.0 | 5 - 1000 | 0 - 40 | -40 to 200 |

| Rotameter | ±3.0 | 0.5 - 50 | -1 - 5 | -20 to 70 |

Assessing Installation Requirements and Maintenance for Your Gas Flow Meter

Selecting the right gas flow meter involves more than just understanding its specifications. Installation requirements play a critical role in ensuring optimal performance. For instance, the meter's location impacts accuracy. It should be away from bends and obstructions. Any improper installation may lead to flawed readings, costing time and resources.

Consider pipe size and flow velocity while installing. Misalignment or incorrect fittings can cause turbulence, affecting measurement. Always check that the meter aligns with the pipeline. This ensures smooth operation. Remember to leave sufficient space around the meter for maintenance access.

**Tips:** Ensure the installation site has stable temperature and pressure conditions. This minimizes variations that could affect your readings. Regularly inspect connections and seals to prevent leaks. A small oversight can lead to significant issues later.

Maintenance is another crucial aspect. Schedule regular check-ups to confirm the meter's accuracy. Dust and debris can accumulate, leading to errors. Sometimes, this can be overlooked until significant discrepancies arise. Use a gentle cleaning method to avoid damaging sensitive components. Keeping track of maintenance history helps identify recurring issues.

Cost Considerations and Budgeting for Your Gas Flow Meter Choice

When choosing a gas flow meter, cost is a crucial factor. According to industry reports, the average price range for high-quality gas flow meters is between $500 and $5,000. This wide range can significantly impact budgeting decisions. Customers often underestimate operational costs over the meter's lifespan. Maintenance, calibration, and energy consumption can add up.

Many users overlook the impact of accuracy on overall expenses. A meter with 1% accuracy might seem cheaper initially. However, errors can lead to cost losses in gas management. Investing in a highly accurate meter can yield long-term savings. Poor choices now may result in high costs later, creating a cycle of product replacement.

Consider installation costs as well. Some meters require specialized setup. This can double the initial expenses. Budget planning should also include training for staff on new technology. Reports indicate that companies often fail to account for these hidden costs. By understanding all aspects, you can make a more informed decision. This ensures your chosen gas flow meter aligns with your fiscal needs and business efficiency.

Gas Flow Meter Cost Considerations

This chart illustrates the average cost of various types of gas flow meters, ranging from low to high ranges, including precision and industrial options. Understanding these costs can help in budgeting and making informed decisions when selecting a gas flow meter that suits specific needs.

Related Posts

-

What is the Working Principle of a Turbine Flow Meter

-

Understanding Digital Flow Meters: The Key to Precision Measurement in Modern Industries

-

How to Choose the Right Gas Flow Meter for Your Industrial Applications

-

7 Essential Flow Meter Types Every Industry Should Know

-

Ultimate Guide to Non Contact Flow Meter Tips for Accurate Measurements

-

Why Choose Magnetic Flow Meters for Accurate Measurement?